1. The traditional RBC biological turntable is overloaded with side pressure and the sludge is not easy to fall off, causing the axis to bend.

2. RBC biological filter material cannot be cleaned and maintained due to too dense biological accumulation.

3. The density of RBC biological filter material is too dense and the biological accumulation cannot fall off, which will cause the motor to overload and increase the electricity bill.

4. The RBC biological filter material is too dense and the biological accumulation cannot fall off, which will cause the axis and bearings to be overloaded and damaged.

5. The RBC biological filter material is too dense and cannot fall off due to the accumulation of organisms, which will cause difficulty in starting during a power outage or power outage.

Excessive weight may easily cause equipment damage. |

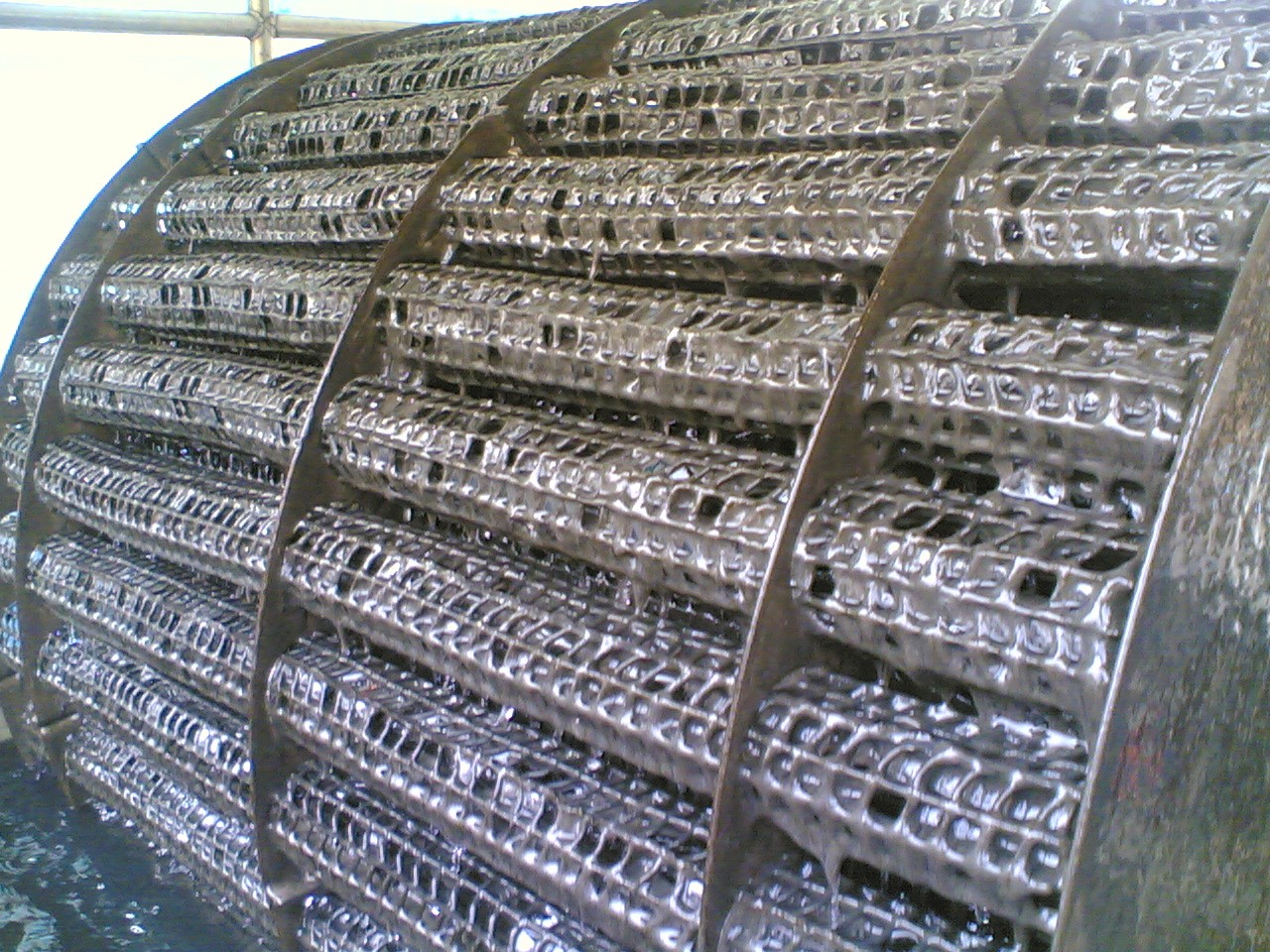

1. The circulation of this filter material must be from all directions so that the sludge can fall off without clogging.

The direction in which sewage enters the filter material is not limited by the traditional membrane type which can only enter water vertically.

Increase its processing capacity after sludge is generated.

2. In order to ensure the normal operation and quality of the system, this unit needs to be a six-piece combined type.

If any piece of filter material is damaged, just stop the machine and remove the side fixing piece, and replace the damaged filter material to restore normal function.

When the service life of the filter material expires, the filter material can be removed and replaced from the side.

There is no need to lift off the tank body to maintain the system and return to normal operating procedures in the shortest time.

3. There must be side clearing holes on the left and right sides of the unit. The biofilm load is too heavy when handling peak volumes.

High-pressure water can be used to force the biofilm to fall off, thereby reducing the load on the shaft and bearings and extending the service life of the unit. |

購物紀錄

購物紀錄  更改密碼

更改密碼  登出

登出

.jpg)